Superfeet Worldwide Responds to COVID-19 by Offering 3D Printing Capabilities

March 24, 2020

Washington State manufacturer offers the technology and production capabilities to quickly address the most immediate needs

FERNDALE, Wash. (March 24, 2020) — As the COVID-19 pandemic continues to spread across the country and place immense strain on the already overextended US healthcare system, Superfeet has opened their doors to help those needing immediate access to 3D printers and/or production facilities to shore up short-term medical supply demand.

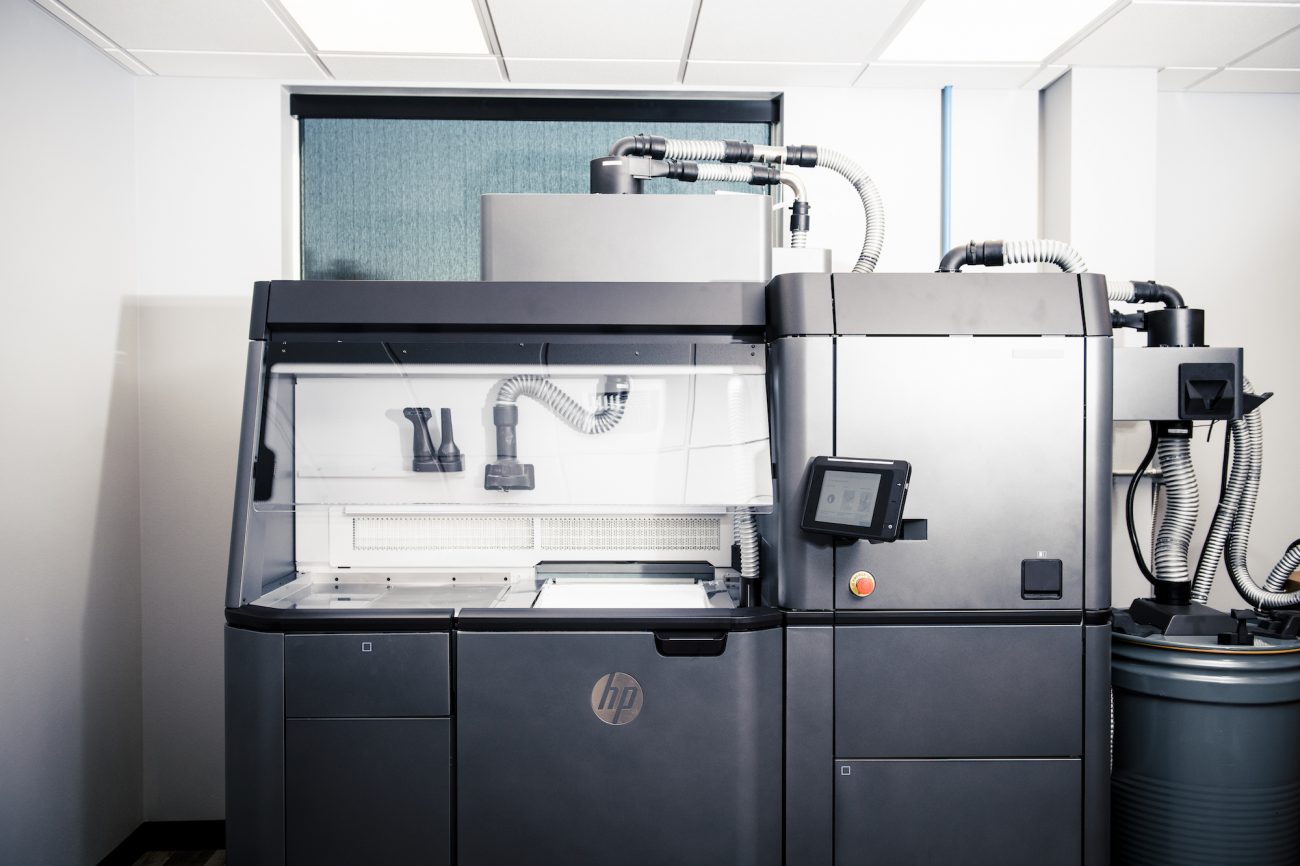

While business as usual takes a pause, Superfeet and their sister company Flowbuilt Manufacturing are hoping to contribute to the safety of our medical professionals and first responders: They’re opening up capacity on their HP MultiJet Fusion printers and setting up a manufacturing line for producing life-saving medical equipment.

Superfeet is asking anyone in need of supplies to combat COVID-19 to reach out to covidresponse@superfeet.com to determine if they can be of assistance.

“The men and women who are our first line of defense when it comes to fighting COVID-19 are facing shortages of the protective gear necessary to keep them safe. We immediately looked at our machines and our team and knew we could do more to help,” says John Rauvola, CEO and President at Superfeet. “We’ve already started the process of prototyping several pieces for medical equipment with our 3D printers and are ready to help create solutions for those in need.”

Superfeet, headquartered in Ferndale, WA (approximately 1.5 hour drive north of Seattle), is 100% employee-owned, and consists of individuals who recognize the power of the greater good. Harnessing the company’s ability to quickly produce custom insoles for customers, Superfeet is now channeling that power to fight the spread of COVID-19.

ABOUT SUPERFEET: For more than 40 years, Pacific Northwest-based Superfeet has been creating innovative products featuring the Superfeet® shape, helping millions of people worldwide experience unparalleled comfort, pain relief and performance. Today, through Fitstation and the latest advancements in 3D-printing technology, Superfeet is taking insoles and footwear from mass-produced products to personalized, made-for-you solutions. A 100% employee-owned company, Superfeet gives 1% of sales and countless volunteer hours to help others shape a strong foundation for a healthy future. For more, visit superfeet.com.

ABOUT FLOWBUILT: Flowbuilt Manufacturing is the only USA based full-service footwear manufacturing facility to offer mass-customization through proprietary multi-section injection technology. Clearing the way for brands to design and deliver the future before anyone else can, the Flowbuilt facility boasts cutting-edge 3D-printers and innovative machinery that flexes easily between creating a single custom pair of shoes to efficiently manufacturing thousands of pairs. At Flowbuilt, ideas flow from design to prototype through products built for today’s consumers, all under one roof. Learn more about Flowbuilt Manufacturing at: https://www.flowbuiltmfg.com/

###